- #Pro engineer creo elements pro update#

- #Pro engineer creo elements pro software#

- #Pro engineer creo elements pro windows#

Designing using software decreases the probability of errors in designing process that could occur when designing manually. To reduce human efforts and improve the accuracy of the design software known as AUTOCAD was developed that is a drafting tool, earlier it was used for 2D drawings and nowadays 3D drawings can also be designed in it. Engineering Drawing is a subject that comes in the engineering curriculum that teaches drawing models using a drafter. The process of designing includes number of stages like research, conceptualization, design requirements, production planning and tool design, and production. This capability enables concurrent engineering - design, analysis and manufacturing engineers working in parallel - and streamlines product development processes.Designing is a process that is carried out by the engineers to create functional products or processes.

#Pro engineer creo elements pro update#

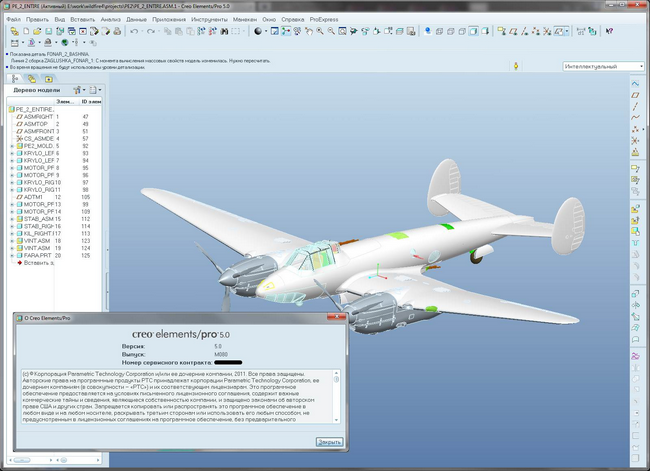

The associativity functionality in Creo Elements/Pro enables users to make changes in the design at any time during the product development process and automatically update downstream deliverables. A product and its entire bill of materials (BOM) can be modeled accurately with fully associative engineering drawings, and revision control information. All data is associative and interchangeable between the CAD, CAE and CAM modules without conversion. The models consist of 2D and 3D solid model data which can also be used downstream in finite element analysis, rapid prototyping, tooling design, and CNC manufacturing. These required capabilities include Solid Modeling, Surfacing, Rendering, Data Interoperability, Routed Systems Design, Simulation, Tolerance Analysis, and NC and Tooling Design.Ĭompanies use Creo Elements/Pro to create a complete 3D digital model of their products. Creo Elements/Pro provides a complete set of design, analysis and manufacturing capabilities on one, integral, scalable platform. This design approach is used by companies whose product strategy is family-based or platform-driven, where a prescriptive design strategy is fundamental to the success of the design process by embedding engineering constraints and relationships to quickly optimize the design, or where the resulting geometry may be complex or based upon equations. The parametric modeling approach uses parameters, dimensions, features, and relationships to capture intended product behavior and create a recipe which enables design automation and the optimization of design and product development processes. Geisberg in the mid-1980s, Pro/ENGINEER was the industry’s first successful rule-based constraint (sometimes called “parametric” or “variational”) 3D CAD modeling system.

The Pro/ENGINEER name was changed to Creo Elements/Pro on October 28, 2010, coinciding with PTC’s announcement of Creo, a new design software solutionĬreo Elements/Pro (formerly Pro/ENGINEER), PTC’s parametric, integrated 3D CAD/CAM/CAE solution, is used by discrete manufacturers for mechanical engineering, design and manufacturing.Ĭreated by Dr.

#Pro engineer creo elements pro windows#

The application runs on Microsoft Windows and Unix platforms, and provides solid modeling, assembly modeling and drafting, finite element analysis, and NC and tooling functionality for mechanical engineers. It was the first to market with parametric, feature-based, associative solid modeling software. Creo Elements/Pro, a product formerly known as Pro/ENGINEER is a parametric, integrated 3D CAD/CAM/CAE solution created by Parametric Technology Corporation (PTC).

0 kommentar(er)

0 kommentar(er)